Since 2005, POLYVA focuses on Overall solution for water-soluble film packaging.

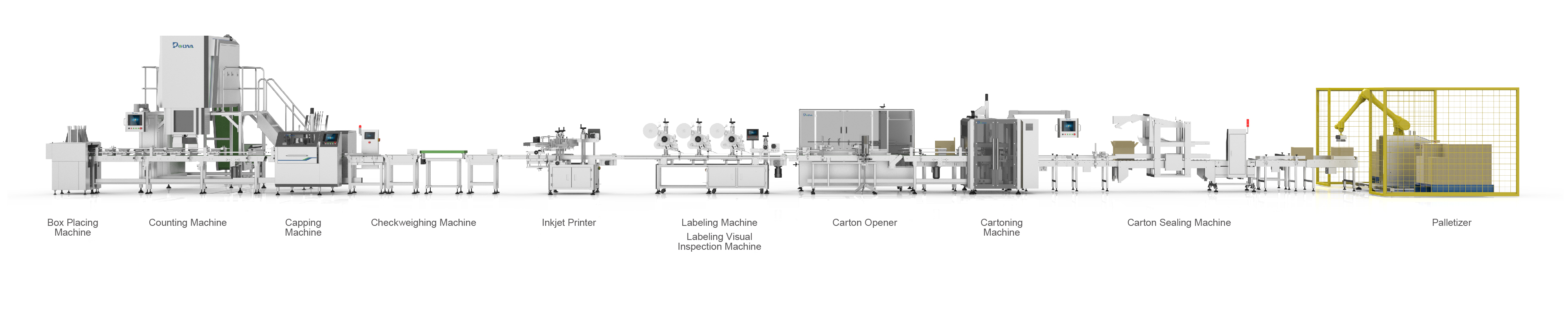

Laundry Pods Turnkey Packaging Solution

no data

main production machine introduction

Polyva's pods packaging line is a fully automated boxing solution that meets CE safety standards. It requires only 2-3 people to achieve large-scale, stable production of pods with high packaging efficiency. The entire line adopts a modular and standardized design, is compatible with various pod forms, and ensures high first-pass yield and finished product consistency through a 6-fold detection and anomaly diversion mechanism, helping brands and OEM/ODM factories improve efficiency and quality control.

no data

no data

no data

Our advantages

Polyva focuses on laundry detergent pods and water-soluble packaging, providing complete packaging solutions from molding and filling to counting, boxing, capping, and cartoning. With a core of systematic design and mass production engineering thinking, Boway helps brands and OEM/ODM factories achieve efficient, stable, and sustainable automated production.

FAQ

1

What is a laundry pods turnkey packaging line?

It integrates forming & filling, counting, cartoning, capping, and case packing into one automated line for continuous and efficient packaging.

2

What are the advantages of a turnkey packaging line?

All machines and line speeds are planned together, reducing integration risks and ensuring stable, efficient operation with less labor.

3

Can one line handle different pod sizes and shapes?

Yes. The modular design supports different shapes, weights, and counting modes through quick parameter adjustments.

4

Is the equipment safe and compliant for export markets?

Yes. The entire line is CE compliant, with clear, visualized structures for safe and reliable operation in global markets.

no data

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Contact Us

FOSHAN POLYVA MATERIALS CO., LTD.(Türkiye Office)

Authority: Muhammet Ali ACAR

Email: macr@polyva.cn

Contact:+905557526858

Address:Köseler, Kocaeli KOB Organize San. District, 25. St. No:6 Floor: 1 41455 Dilovası/Kocaeli

Copyright © 2025 POLYVA | Sitemap | Privacy Policy